The Ssangyong Stavic had a check engine light and lost power. A quick probe of it said it had an EGR issue which started a couple of month saga.

I gave the nearest Ssangyong dealer a call and ordered a valve that was in stock down in Melbourne. I got a call back saying it wasn’t on the shelf so they would have to order it from Korea. I then decided to try to fix the problem myself.

The valve was held in place by 5 bolts, 3 of them being easily accessible, 1 not so much and the final one taking 6 hours to undo. I should have taken everything off the side of the engine to access the difficult bolt.

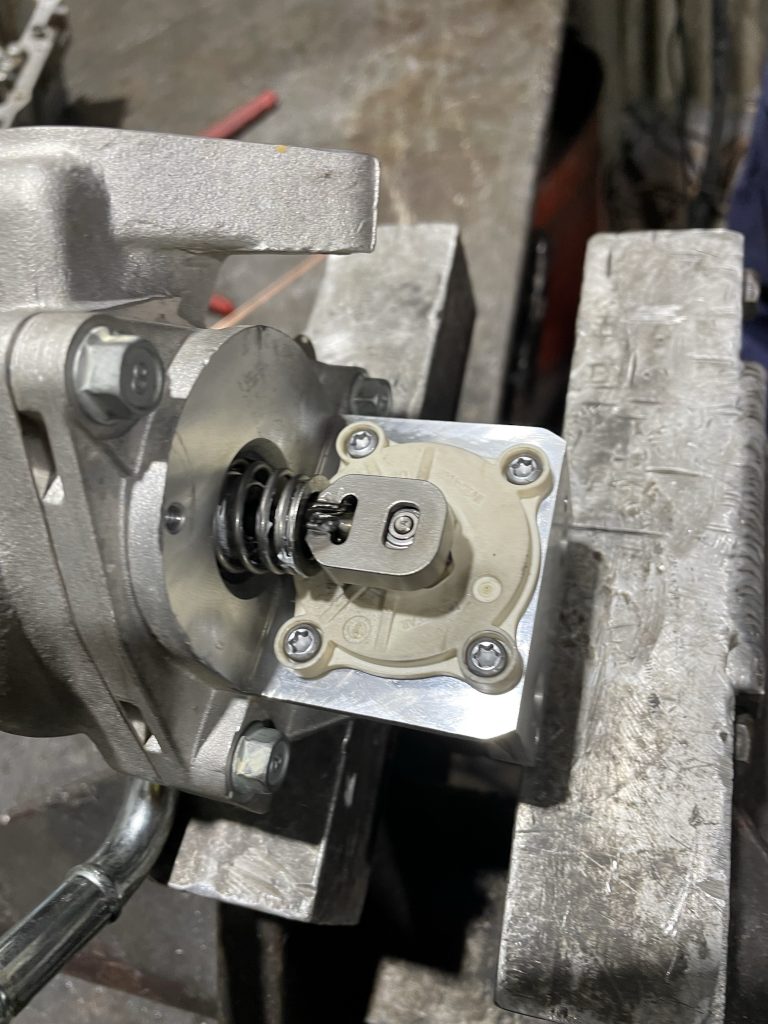

After removing the EGR valve I pulled the top cover off and found that the cam had broken.

The rocker was welded to the shaft so I spent an hour and 4 dremel bits grinding the weld out

I then added a Philips head the the problem bolt so I could get it in most the way then only have to tighten it

This then came off when I tried a dry install so I went with plan B. I purchased a set of cheap ball head Allen keys and welded it on to a shaft and welded a head onto the bolt

I then re-installed the EGR valve and it ran pretty well for a bit than ran rough then stalled. I had disconnected the diesel to the high pressure pump. and suspected there was air in the line. After a couple of minutes retrying the car then ran smoothly and had all its power back. Unfortunately this was not going to last.

The car broke down about a fortnight after the repair when Amy was doing school Dropoff during morning peak hour. Luckily a Good Samaritan pushed the car off the road into an Aldi carpark, where the RAC came to tow the car to the mechanic. They diagnosed the issue as the EGR valve ( there were no error codes) which still hadn’t arrived in Australia yet but did block off the line which allows the car to at least start. It had no power until the engine revs reached 2500rpm but if it wasn’t revving it couldn’t make it up a hill from a standing start as the engine couldn’t get up to those revs.

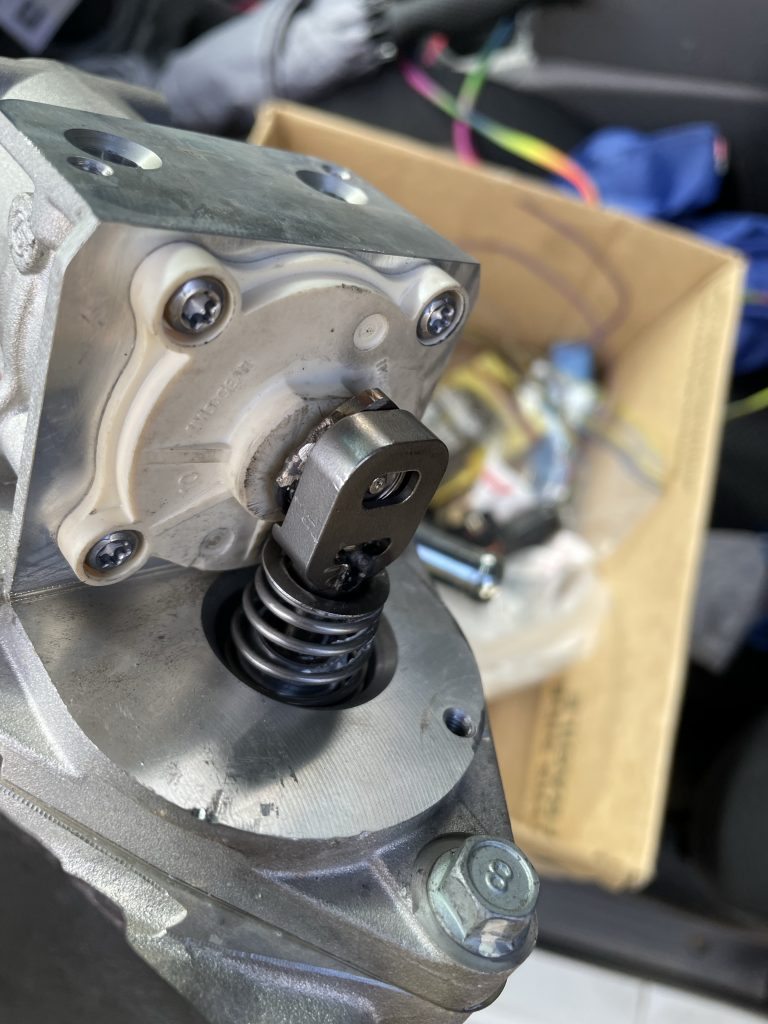

The new valve arrived 3 months after I first ordered it. I was tempted to swap the cap with the position sensor with the one on the car but decided against it as I had this brand new assembly and don’t want to touch it again in 6 months.

After pulling the old EGR valve off I found what was the cause of the new issue. Gasket goo blocking off most of the water gallery to cool down the electronics in the valve.

This could explain why it worked at first but then stopped after some use. The assembly got hot and cooked the position sensor and was outputting incorrect signal for the position.

The new EGR valve worked straight up and the car works nearly as good as before. The only difference is there appears to be a little more lag accelerating from standstill as the partial blanking valve is still installed. I’ll pull it out one day.