We have an old Hoover dryer that the motor bearings were making a terrible noise in. I “repaired” it and the power tripped.

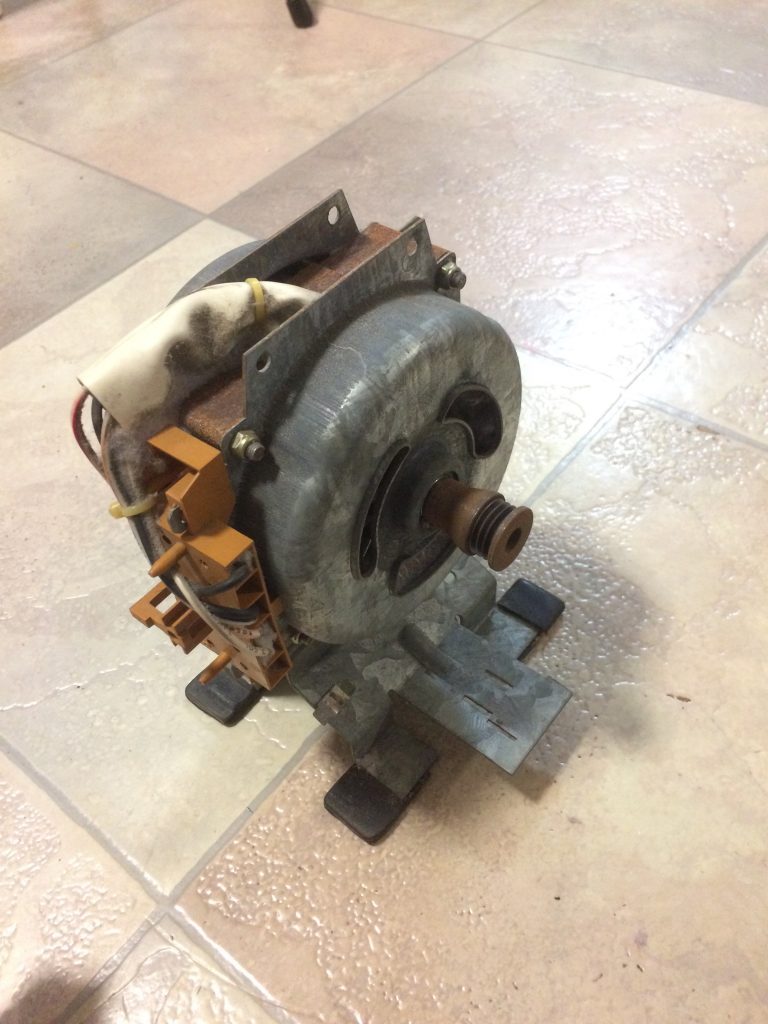

I would love a new heat pump dryer to reduce power consumption, but we are on a no-spend-year imposed by my awesome Wife Amy, and we have enough excess solar power during the day that the payback period is a while. If the bearings in the motor seize then a thermal fuse in the windings blows and a new motor is then required. As I prefer to spend money on food than a whole new dryer I thought I would be proactive and change the bearings before they gave out.

After getting the bearings out with the help of Greg from G&L manufacturing, I put new bearings in and put the dryer back together. I had left the disassembled dryer under the verandah outside near where it usually resides. It had been raining but was far enough under than it was protected from the spray.

After powering it up for the first time the RCD in the house tripped. I thought I had damaged the windings of the motor to cause the problem, but after a bit of testing found that the heating element had a relatively low resistance to earth that was causing the problems.

The heating element used in this dryer is a high resistance material surrounded by a mineral insulator encased in a steel tube. Both ends are supposed to be sealed to stop water ingress, but this is not always the case.

Being left outside partially disassembled enabled the element (the mineral insulator) to absorb moisture to cause a fault to ground. This is not uncommon and requires the moisture to be baked out. The best way to do this is to power up the element and let it cook out the water. The problem with my house (and should be the same everywhere) is that all power points are RCD protected so will not allow the dryer to turn on to do such a thing. Thus comes in my bypass.

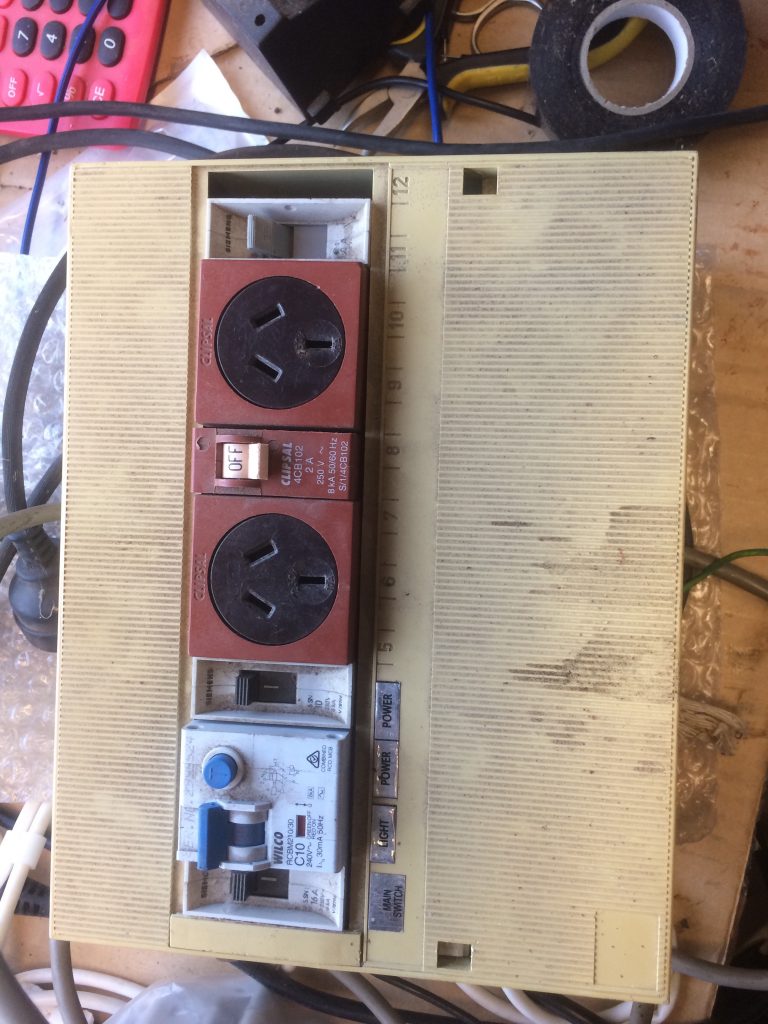

This unit allows me to move the earth of the device being plugged in /tested to 1 of 3 positions.

To supplied earth- this is the normal and means the device is fully protected by the supply protection.

To the neutral before the RCD on the unit – this allows any earth faults to be detected by the inbuilt RCD and does not trip the house supply and not annoy Amy when she is trying to remote into work. Any current from the earth wire returns on the neutral.

To neutral after the RCD – this stops the inbuilt RCD from tripping on an earth fault while the device is insulated from anything grounded. Any current from the earth wire returns on the neutral.

This last one is what I needed to power the dryer to cook out the moisture in the element. It also allows me access to measure the current or potential voltage of the earth to active/neutral. When I first powered it up I had 0.5A on the earth conductor from the dryer which is huge. This fairly quickly went down to about 250mA, after which I left it on for an hour which saw the reading go to below 0.25mA. I was happy with this, and now Amy is happy with me now we have a working dryer again.